I love a good fibre story.. especially one where I have a personal connection to the fibre source. When you put so much time into something (that not many people get to experience for themselves) it is always a pleasure to be asked about where it came from or how it was made.

So this fibre story starts with one of our 2021 alpaca fleeces. This time it was our floofiest girl ‘Golfy’ that gave this beautifully long, super soft fibre in a lovely light fawn colour.

It had been a wet and muddy year so her fleece needed a good clean before I could do anything with it.

I started by hand picking, where I was a lot better at removing all of the rubbish this year – its not worth keeping every little fibre if you end up having to stop and pick bits out while you are spinning. I am not wasteful, but I have plenty of fleeces to choose from at the moment so its not so hard to make good decisions about what to keep – I know I’m not going to run out!

The dirty fibre goes into my purpose bought wash basket, the lid is clipped on and it gets a good blast from the garden blower. It amazing how much dirt flies out! Alpacas love to roll around on the ground, and even in the greenest paddock they will wear down a patch of dirt to roll in. So a years worth of dirt, leaves, bits of grass etc gathers amongst the fibres until shearing day and beyond.

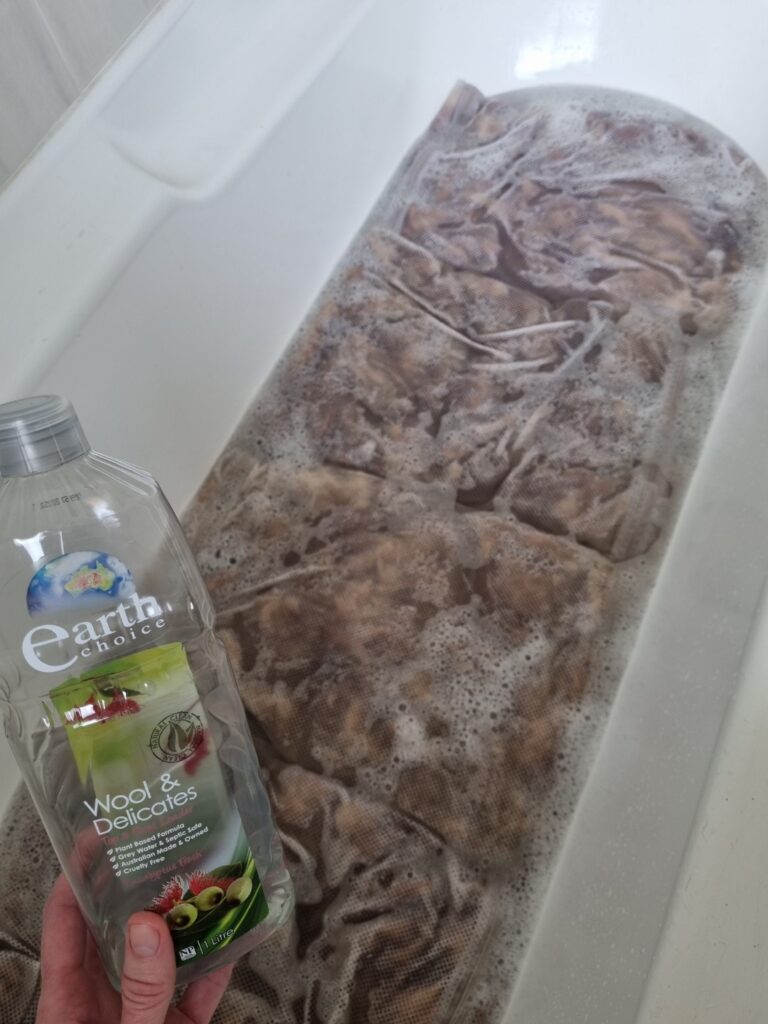

After I have blasted as much dirt out as I can, I put the fibre into laundry bags, and soak a few bags at a time in warm water and a bit of wool wash.

I just sit the bags in the water, gently press them down and then walk away and leave them.

Sometimes I forget to go back and they soak for hours! It is important that the fibre is not agitated and also that I don’t do any crazy water temperature changes, or it will ‘felt’ and be ruined.

After soaking, I gently lift the bags and squeeze the excess water out. I fill the laundry tub with cool clean water and do the same thing to rinse. It can soak, or if I’m in a hurry, carefully moving the bags under running water seems to be OK.

Once the water is pretty much clear, I drain off the excess water and put the bags into the drum of my washing machine and set it to spin. I have found that setting the machine to skip straight to the spin cycle (no rinse etc) gets the washed fleece as dry as possible before laying it all out of its bag onto a sheet to dry.

Sadly, that’s about as clean as I will get it for now, yet it is still full of bits and pieces that need to come out! This is enough to put some people off working with alpaca – or raw fleeces in general, but it doesn’t bother me. I’m not under any great pressure and I don’t need to hurry so I just do a bit when I am in the mood and get it done.

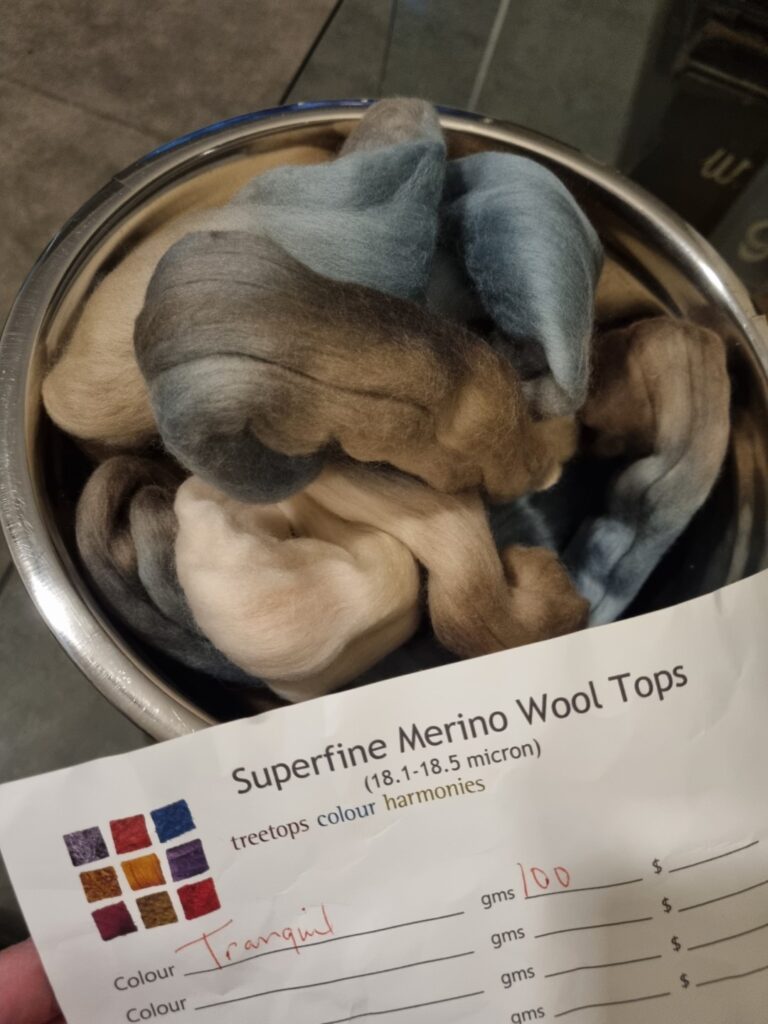

To create a yarn that is less likely to stretch over time, I decided to add some merino fibre to the mix. To keep things interesting, I started with some nice earthy toned, dyed merino from Treetops Fibre (‘Tranquil’ colourway) and then topped up the mix with some undyed superfine merino (that I still have left from a bag of fibre that came with my second hand spinning wheel nearly 2 years ago)

Each bundle is carefully weighed out to end up with piles of 50/50% weight alpaca and merino.

Picking, blowing and washing the alpaca fibre is just the beginning when you are working with fleece from your own lawn mower! Next, I send the alpaca fibre through my drum carder. It goes through once pretty quickly just to get it roughly ‘organised’.

On the 2nd pass through, I sit and watch it go around and pull out any really obvious bits of leaf, grass, second cuts etc with tweezers, although most of it just falls out onto the tabletop while the carder combs and pulls the fibres through.

Preparation really is the key here – less bits in it now, the smoother the spinning will be later because I won’t have to stop and pick it all out as I go.

It is a slow process but Little Cat is always nearby to keep me company!

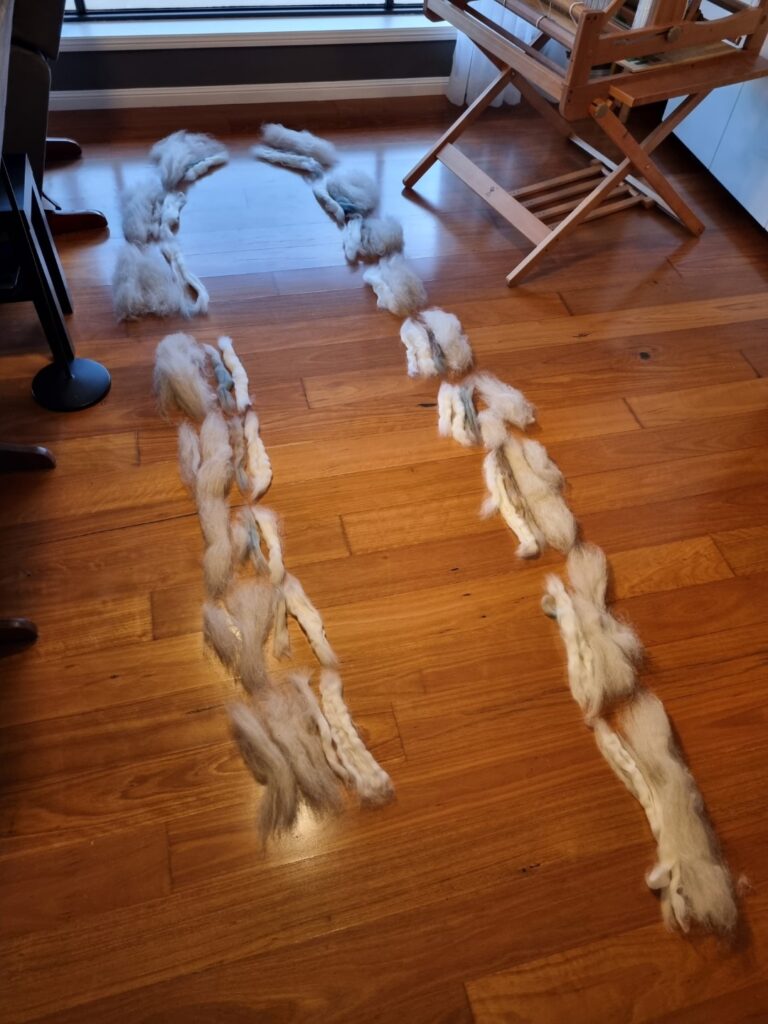

It gets a bit easier from here – and it’s the more creative bit too! The final time through the drum carder is about mixing my bundles of fibre into little batts that I hold while spinning.

For this project I am purposely keeping the colours in separate sections as I blend. So after laying the treetops merino strips (the dyed bits) out on the floor, I distribute the plain merino and clean/carded alpaca along the length so that the blend will be evenly mixed. I am hoping the knitted yarn will have a nice subtle and even spread of the different tones that you can see in the original bag of ‘Tranquil’ fibre.

One of the things I love about spinning my own yarn is that I get to choose what goes into it.. and in this case I will end up with something close to a 50/50 alpaca/merino blend. The alpaca keeps it soft, warm and maybe a little bit drapey (and its free!) and the merino is also soft and warm, but adds a bit of springiness and elasticity to hopefully keep the garment in shape over time.

I’ve got big plans for this yarn. After the success of my first big hand spun project (‘Ankers summer shirt’) late last year, I am super keen to make myself something a bit more wintery this time. I am confident I can make a full jumper now, so I will be looking for a style that is a little looser, longer and with long sleeves.

One of the challenges of producing the amount of yarn I need for a full jumper, is keeping the thickness of the single strand pretty even. I do tend to vary a little bit, but it seems to even out when I ply the strands together.

For this project I am using a technique called ‘chain plying’ and it will end up with 3 strands twisted together to make the final yarn. Its not from 3 separate bobbins though.. I get the 3 strands by creating an ongoing chain from the one bobbin.

I had never done this method before, so it took a bit of practice, but I am pretty happy with this technique now. The reason I wanted to do it, is because it allows me to keep those colours batched together. If I was to ply 2 different strands together (from 2 separate bobbins) there would be no way of knowing what colours are going to twist together at any time.

With the chain ply, you are twisting one single strand of fibre that is pretty much from the same little section of fibre that it started with.

That probably makes no sense to a non-spinner haha. You are just going to have to trust me.

After plying, I remove the yarn from the bobbin by wrapping it around a niddy noddy (of all the things I didnt get a photo of, it was that step haha) This creates a big loop of yarn that is loosly tied to avoid tangles before giving it another wash.

Once dried, I finish my yarn preparation by twisting the loop into a skein to store, or by winding it into a ball ready to knit.

So with a jumper worth of yarn, the next challenge was choosing a knitting pattern to use. I thought I knew.. I had done a test swatch, chose my needle size and got started on one pattern, only to change my mind.. twice..

You’ll have to stay tuned for my finished jumper! I’ll share that make on another day

1 thought on “Slow and steady.. but learning new things and loving the journey”

Nice post!